vickers hardness test lab report conclusion|hardness tester lab report pdf : custom CONCLUSION: The Vickers hardness test is easy to use and its benefits far . INDICAÇÕES: Bravecto ® é indicado para o tratamento de in.

{plog:ftitle_list}

Olhe-se no espelho e diga para si: “Eu não preciso disso!”. Porque, de fato, você não precisa. Ame-se mais, que você vai parar de gostar desse ficante na hora. Copiar. .

Vicker’s hardness test to determine the hardness of a sample metal that was given to us. This test is done by making a dent on a metal using a diamond indenter which is in the form of a .Conclusion: The purpose of this experiment was to determine which of the five .CONCLUSION: The Vickers hardness test is easy to use and its benefits far . From table, it can be concluded that most of the point on the sides specimen 1 have highest Vickers hardness number compared to the middle .

Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable for the production of 500 HV30 automobile .

CONCLUSION: The Vickers hardness test is easy to use and its benefits far outweight any potential disadvantages include during the experiment of hardness testing with any type of material to measure the hardness of each material.

(I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.

Rockwell hardness test. Use ASTM E 140-88 "Standard Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell .Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness .

Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. The advantages of the Vickers hardness test are that .VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: .

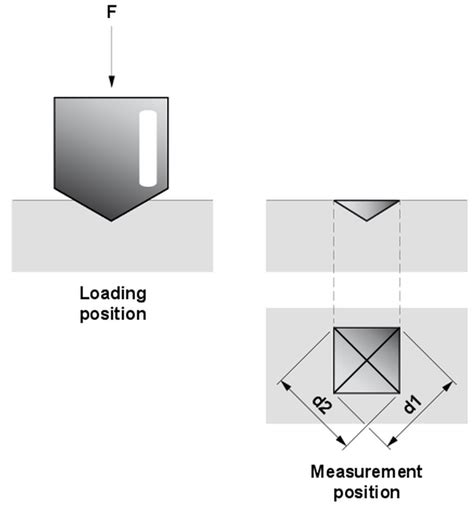

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .

Vickers hardness test Introduction The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative.lab report 03 materials engineering experiment no. 02 rockwell hardness test of given sample introduction: hardness of material is generally defined as . The hardness test is a mechanical test for material properties which are used in .How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . The Vickers hardness test is a versatile hardness test method, used for both macro and .

5. PAGE 4 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs. . The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not .Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.]For most hardness testing, 50 kg is maximum. The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH). The hardness number can be calculated by the load over the surface area of the indentation .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .LAB REPORT VICKERS HARDNESS TESTING NAME CLASS NUMBER MATRIC. MUHAMMAD AFFAN AKMAL BIN ABDUL RAHMAN. DKM 3D 08DKM21F. MOHAMAD HAKIMI BIN ROSMAWI . CONCLUSION: The Vickers hardness test is easy to use and its benefits far outweight any potential disadvantages include during the experiment of hardness testing with .

Infinita Lab further enhances this utility by offering a comprehensive catalog of 2000 material science tests, including the Vickers hardness test. With a network of accredited testing laboratories spread across the United States & offices in 16 strategic locations, Infinita Lab caters to a broad spectrum of industries. Vickers hardness testing also is known as the Diamond pyramid hardness test. Because we use the Diamond pyramid as the indenter. The same testing machine which is used for the Brinell hardness testing machine can be used for the Vicker’s hardness test also.; Unlike Brinell hardness testing, we do not need to change the indenter for the different materials. we .The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

The Vickers hardness test is based on the same principle as the Brinell test, except the indenter is a diamond pyramid with square base. The angle between the faces of pyramid is . considered in lab report. Lab Report Requirements 1. Results List hardness values of Rockwell and Brinell for each specimen.PDF | On Aug 27, 2023, Dokta Urame published EN113 Lab 02 Brinell Hardness Testing Report | Find, read and cite all the research you need on ResearchGate . Rockwell and Vickers or Knoop but in t .

Lab report of Experiment 7: Hardness Properties of Materials. The objectives of this experiment are to determine the importance of hardness on selection of . In the Vickers hardness test, tool steel also had the highest value of hardness .

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .HARDNESS TESTING* PURPOSE . Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, and Knoop Hardness)" to convert the BHN to RB and vice versa. Are the . LABORATORY REPORT 1. Include the following information in the laboratory report. 6061-T6 aluminum 1018 (HR) orConclusion the hardness test experiment was done. Pages 5. Total views 100+ San Francisco State University. ENGR. ENGR 200. mbrambila7. 11/15/2017. 100% (2) . View Lab - Hardness test Lab Report .docx from ENGR 200 at San Francisco State Universi. Lab 2 (Hardness).docx. San Francisco State University. ENGR 200. It.Subject Title: Strength of Materials Course Title: B.Eng. Manufacturing Engineering Report Title: Hardness Testing Student Name: Unknown Fella upload this to help others Student Number: T00***** Assignment Date: 5/5/2020 Presented to: Gary Fort Declaration: I hereby declare that the work outlined above has been completed by myself, it has not been shared with any other .

This paper contains a lab report about hardness test which contains Brinell, Vickers and rockwell hardness measurement methods rockwell hardness lab report . Conclusion. With the help of this experiment, we have been able to relate how hardness of steel samples is affected by variation in carbon content and the rate of cooling applied on the .How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. . when drawing conclusions of a hardness test, you should always evaluate the quantitative value in relation to: The given load on the indenter . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from .%PDF-1.4 %âã 1 0 obj /Title () /Creator (þÿwkhtmltopdf 0.12.5) /Producer (þÿQt 5.11.3) /CreationDate (D:20220203202910+02'00') >> endobj 2 0 obj /Type /Catalog /Pages 3 0 R >> endobj 4 0 obj /Type /ExtGState /SA true /SM 0.02 /ca 1.0 /CA 1.0 /AIS false /SMask /None>> endobj 5 0 obj [/Pattern /DeviceRGB] endobj 7 0 obj /Type /XObject /Subtype /Image /Width .

Vickers Pyramid Hardness Testing Introduction: Hardness is the resistance of a material to plastic deformation caused by indentation. . Discussion and Conclusion: The Vickers hardness test was established in 1921 as an alternative experiment to discover the hardness of different metals. This experiment tends to be easier to use and more .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

difference between volumetric coulometric karl fischer titration solution

7 de nov. de 2021 · Confira onde vai passar o jogo entre Rennes x Lyon neste domingo, 07/11, a partir das 16h45 pela décima terceira rodada da Ligue 1.

vickers hardness test lab report conclusion|hardness tester lab report pdf